Topics: cost optimization, food & beverage, Inflation and Recession

Cutting Costs During Food & Beverage Industry’s Highest Ever Inflation

Posted on November 07, 2022

Written By Siddharth Sujan

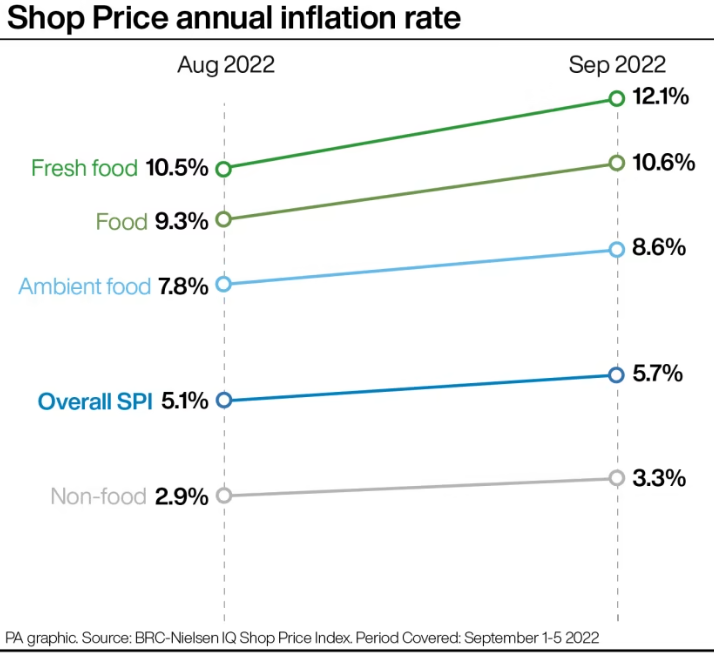

Despite a significant drop in gas prices, food inflation shows no signs of slowing down. According to research by the British Retail Consortium (BRC) & Nielsen IQ, food inflation has hit its highest rate, with consumers in the UK now paying 10.6% more than last year. The supply chain disruptions caused by Russia’s invasion of Ukraine, summer droughts, government-imposed costs and a plummeting pound have all come together to push inflation to new highs, across categories.

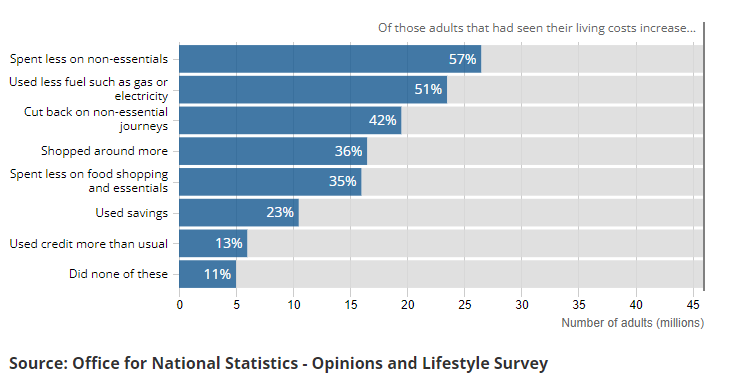

On the one hand, this inevitable cost of living crisis will result in most households feeling the fiscal punch, at least in the long run. On the other hand, food & beverage manufacturers are also expected to face the brunt of sky-high operational costs and as a result, struggle with maintaining their bottom line.

Let us dive deep to understand the factors behind this acute food inflation and then look at some strategies owners & executives can adopt to address these challenges.

Factors Causing Food & Beverage Inflation

THE BIG ENERGY CRISIS

Amongst the most significant implications of the Russia-Ukraine war, gas supplies into Europe have dwindled over the past few months. This has pushed the UK into its worst energy crisis in years – affecting households and businesses alike. For an industry whose 10-15% of the operational cost comprises energy, a two- to three-fold increase in fuel & electricity costs is hurting food & beverage manufacturers significantly. Although there have been some policy interventions in the last few months, the end consumers will feel the rising energy costs.

TRANSPORTATION COSTS

Over the last year or so, leading food & beverage companies have been faced with a unique challenge. Even after overcoming all the internal operational difficulties, manufacturers find themselves with ready-to-ship products sitting in warehouses. The UK trucking industry continues to reel under the after-effects of the global talent shortage, alleviating the ongoing F&B supply chain issues. As a result, companies are left with no choice but to pump in more money in expanding their in-house fleets to ensure that their finished products reach the right place at the right time.

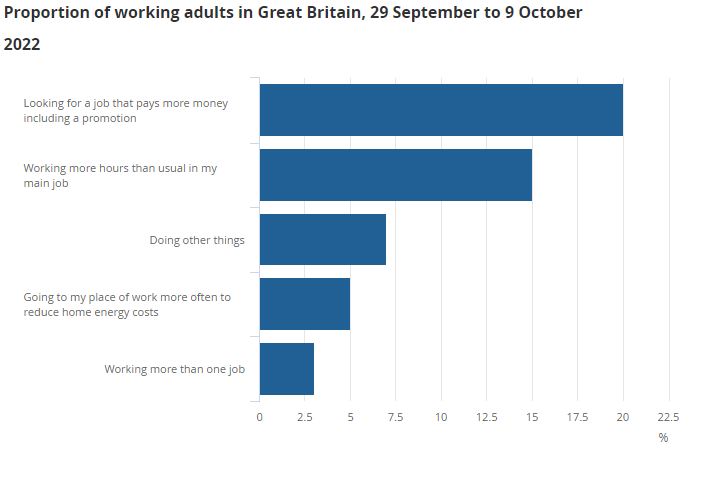

RISING TALENT COSTS

Much like other industries, the food & beverage sector too has been a victim of the Great Resignation, with companies of all sizes finding it challenging to attract & retain talent. The acute labour shortage has forced businesses to increase wages by 15-25% – a previously unheard-of trend that seems to be becoming the new industry norm. According to a survey conducted in March 2022, 60% of businesses in the food and beverage sector reported a low number of applications for the roles on offer – numbers that clearly indicate that high talent costs will continue to trouble F&B manufacturers in 2023 as well.

Reducing Food & Beverage Manufacturing Costs

With inflation accelerating across the economy, supply chain disruptions becoming common and talent shortage continuing to affect businesses across sectors, food & beverage manufacturers will have to take measures to limit the impact and not pass cost increases on to customers. Let us look at some broad strategies that can help optimize food & beverage manufacturing costs:

FLEXIBILITY IS THE NAME OF THE GAME

One common realization that has helped businesses immensely in the post-COVID landscape is that flexibility holds the key to gaining an edge over the competition. In the context of the food & beverage industry, building a flexible manufacturing line allows businesses to cater to changing consumer behaviour, while ensuring quality consistency.

Many forward-thinking companies are taking this to the next level by moving to flexible operating models and setting up shared service and GBS centers that not only help bring down operational costs directly but also consolidate & optimize processes across the board to deliver consistent cost savings.

AUTOMATION TO THE RESCUE

While some businesses cut down on technology investment to achieve immediate cost savings, forward-looking organizations look at the potential of automation tools and take the opposite route. Replacing legacy, people-based processes with smart solutions help reduce dependency and overcome costs involved in hiring & retaining staff.

In addition, solutions like inventory management and supply chain management systems go a long way in optimizing the entire manufacturing cycle and enhancing the consumer experience, adding to the labour arbitrage savings.

RELATED BLOG: Digital ordering systems can go a long way in helping businesses better manage procurement to maximize efficiency & profits. Read on to know how restaurants are using these tools to transform their P2P process.

FUTURE-READY APPROACH

Much has been spoken about the importance of data & analysis in optimizing food & beverage manufacturing but in reality, only a handful of these businesses utilize their full potential. Adapting a forecasting method can be a game changer, especially during an economic meltdown, as it helps manufacturers avoid excessive inventory and unnecessary production.

Predictive analytics solutions, for instance, utilize existing & past data to alter production basis potential demand trends, market prices and geopolitical scenarios, thus future-proofing companies in their truest sense.

Where Do We Fit In?

Cost optimization projects, especially those involving technology implementation and operational redesign, require a high level of expertise which in-house teams might often lack. Support of a reliable transformation expert like QX Global Group can be the make-or-break factor in such situations. Contrary to age-old myths around sourcing, modern third-party partners can work closely with your in-house teams to understand your specific business challenges and identify cost optimization solutions.

We, at QX Global Group, follow a unique People-Process-Platform approach that allows us to enable & accelerate transformation for our clients. Our end-to-end consulting, technology and BPM solutions are are tailored to meet your specific challenges and can help optimize costs by up to 50%! Connect with our team of transformation experts to schedule a free, no-obligation consultation today.

Originally published Nov 07, 2022 06:11:55, updated Apr 07 2025

Topics: cost optimization, food & beverage, Inflation and Recession